Need bottles or containers? We have you covered with our Blow Molding capabilities.

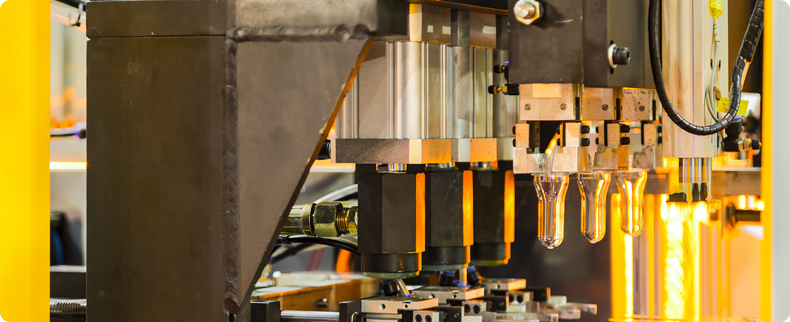

PTC offers two styles of blow molding: injection stretch and extrusion.

The Injection Stretch process begins with an injection molded perform. The perform is typically pre-heated then stretched in the axial direction and blown into its final shape by a stretch blow molding machine. In the Extrusion process, plastic is melted and extruded into a hollow tube. This tube is then captured by closing it into a cooled metal mold. Air is then blown into the tube, inflating it into the desired shape.

With the two styles of molding, PTC has the capabilities to produce bottles and containers in various sizes, neck finishes and materials.

Facts about PTC’s Capabilities

- Specialize in manufacturing reusable water/mixer bottles

- Capacity to make 10MM+ bottles per year

- Can produce and pack out reusable bottles in one facility

- Provide best in class efficiency and speed to market

- Ability to mold bottles up to 128 oz

- Capable of using PET, Tritan, PP, and PE plastic materials

- Blow molding since 2010